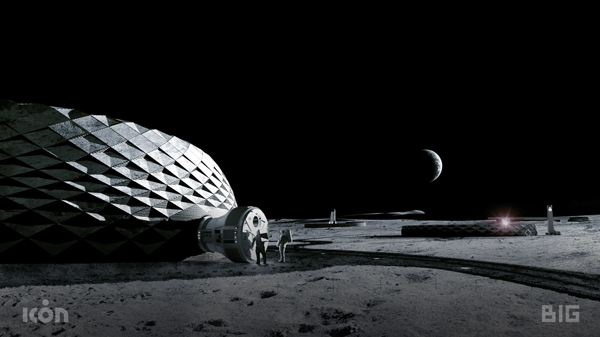

What NASA’s 3D-printed moon base means for the rest of humanity

Back in 2021, Danish architecture firm Bjarke Ingels Group (BIG) announced its collaboration with construction technology company ICON and NASA to create Mars Dune Alpha, a 3D-printed structure designed to simulate life on Mars.

The 1,700-square-foot “habitat” essentially aims to help NASA understand the physical and mental challenges that may impact crew on a long-term space mission and ultimately prepare humans to live on the red planet. Comprising four private crew quarters, a shared living space, and work, medical and food-growing stations, the ceiling heights of the infrastructure vary in order to ensure each room is visually unique to avoid spatial monotony and crew member fatigue.

Featuring customisable lighting, temperature, and sound control, Mars Dune Alpha was dubbed the “highest-fidelity simulated habitat ever constructed by humans.” During the development of the structure—which is now set to be used during NASA’s Crew Health and Performance Analog (CHAPEA) mission in 2023—experts unlocked the potential of 3D printing and deemed it an essential part of humanity’s toolkit to becoming a multi-planetary species.

Come late 2022, ICON then landed a $57.2 million contract for NASA’s Project Olympus—the space agency’s efforts to develop 3D-printed bases on the moon using materials solely found on its surface. Here’s why the project matters and what it means for our dreams to expand into the beyond.

ICON and the promise of a long-term lunar presence

Known for building cheap 3D-printed homes and military barracks on Earth, Austin-based startup ICON was founded by Jason Ballard in 2017 with the aim of solving the global housing crisis. Constructing neighbourhoods in several US states and Mexico, the company builds homes with a proprietary material between mortar and concrete, printed in place using ICON’s machines.

Now, the startup is hoping to bring the material cost for building structures on the lunar surface down to zero. “If we’re going to be the advanced civilization we say we are and think we are, we ought to be better at sheltering ourselves,” Ballard said in an interview with Payload. “We must have ways of sheltering ourselves that don’t ruin this planet in the first place.”

As part of the $57.2 million Phase III Small Business Innovation Research (SBIR) contract, ICON is set to take its 3D printing technology for a demonstration on the moon in 2026—assuming that NASA’s schedule for its Artemis mission, which seeks to land the first woman and first person of colour on the moon, remains intact.

According to Ballard, the demonstration will use actual lunar regolith—the rocks and dust that make up the surface of the moon—to build a structure that meets NASA’s strength requirements. While the startup uses water-based material to build structures on Earth, water sublimates on the moon. It would also be expensive to transport additives to mix in with lunar regolith all the way from Earth.

“If you tried to plan a lunar settlement or a moon base, and you had to bring everything with you every time you wanted to build a new thing, it’s like another $100 million,” Ballard said. “But once you’ve got a system that can build almost anything—landing pads, roadways, habitats—and it uses local material, you are probably two or three orders of magnitude cheaper to build a permanent lunar presence than you would be in any other way that we can think of.”

In 2021, Doctor Aled D. Roberts from the Future Biomanufacturing Research Hub announced that the perfect solution to building structures on both Mars and the moon is… human blood. “[Like cows], humans also produce this protein which can be used to stick together moon dust, Mars dust or sand—and any space mission which is crewed would have humans present,” Roberts told SCREENSHOT at the time.

In a paper published in the journal Materials Today Bio, the expert and his team discovered that human blood protein, when paired with both Moon dust and Mars dust, created a very strong, concrete-like material. “We found how it was sticking together, and based on our understanding, found that compounding this with Urea (from human urine) increased the effect of the bonding mechanism,” Roberts said.

Although he delivered a healthy dose of realism into the sci-fi-esque scenario by stating that the mixture would probably only be used for motors or to stick sandbags together, Roberts also acknowledged how there’s a significant delay in communications between Mars and Earth. “It can take around 40 minutes for communication between the two planets—if the astronauts are in a life-threatening emergency, they would essentially have to fend for themselves,” he explained. “It’s useful to know that they could potentially make strong hard materials using their own blood and urine.”

Back to ICON, the startup claims that it can construct its 3D-printed moon bases by first fine-tuning the printer’s laser based on the chemical makeup of the specific sample of regolith being used, then laying down a layer of regolith, using the laser to melt the regolith into a ceramic structure, laying down another layer of regolith on top, and rinsing and repeating. ICON has already tested this approach using simulated regolith in vacuum demonstrations on Earth.

Insights for a better future on Earth

When it comes to space technologies, it’s worth noting that they almost always have a trickle-down effect which eventually influences advancements back on Earth. For Roberts, he believed his research could help humanity find a valuable substitute for concrete, which presently accounts for 8 per cent of global greenhouse gas emissions.

“This is just the start, we could potentially further develop this concept into a technique which uses plant-based proteins or other sustainable resources,” the expert shared. “This could help us find a relatively low-carbon alternative for construction materials like cement, tiles, all that kind of stuff.”

In the case of ICON, Ballard also stated that insights gathered from the 3D-printed lunar project can help solve multiple crises on our home planet. “If you get better at building houses in difficult, harsh, remote environments like the moon, you probably are also going to be better at it on Earth,” he told Payload. “And getting better housing on Earth is also a profound opportunity and problem to solve.”

A number of other architectural firms are also exploring humanity’s presence on the moon as we speak. In 2017, a collection of projects visualised life on the astronomical body for a competition dubbed Moontopia. Two years later, Skidmore Owings & Merrill (SOM) revealed that it had teamed up with the European Space Agency (ESA) and Massachusetts Institute of Technology (MIT) to design an “inflatable moon village” as “the first permanent human settlement on the lunar surface.”

Let’s just hope that, this time around, there won’t be a rogue group of interns who pocket some of the extraterrestrial rocks to take back home, place under their pillows, and later boast that they literally had “sex on the moon.”